Product

LNG Bunkering Simulation System

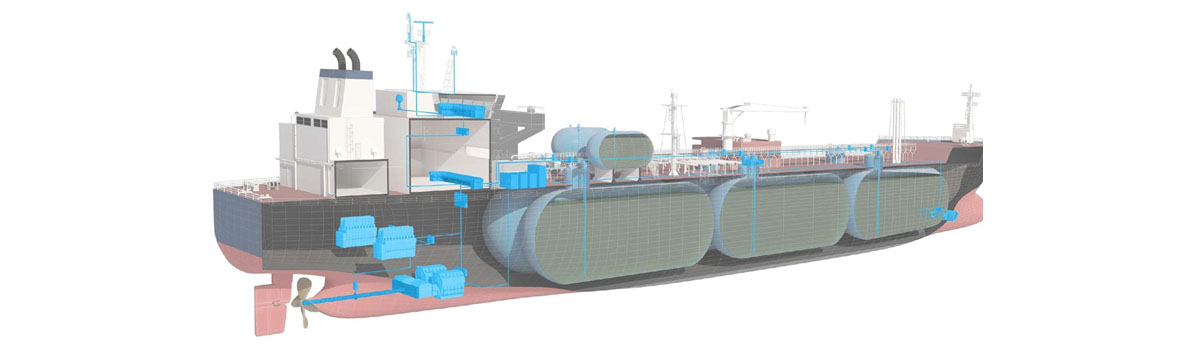

LNG-Fuelled Marine Vessel Training System

According to IMO’s IGF Code of January 1, 2017, personnel working on vessels using gases or other low- flashpoint fuels must be properly trained. These training requirements are further addressed through STCW regulations. Latest LNG Bunkering simulator model, Diesel Electric Dual Fuel Cruise Ferry, enables safe, realistic and efficient training on LNG-bunkering procedures for engineering students and crew. It is specially designed to support IMO’s IGF Code and STCW’s new requirements for basic and advanced training.

Main training elements:

Characteristics of LNG (low flashpoint fuels quality)

Safe working practices with LNG equipment

LNG bunkering operation procedures

Fire prevention

Emergency procedures

Operational principles of dual fuel generator installations

Fuel oil and LNG supply system for diesel generators

Sufficient control relevant for the particular ship type:

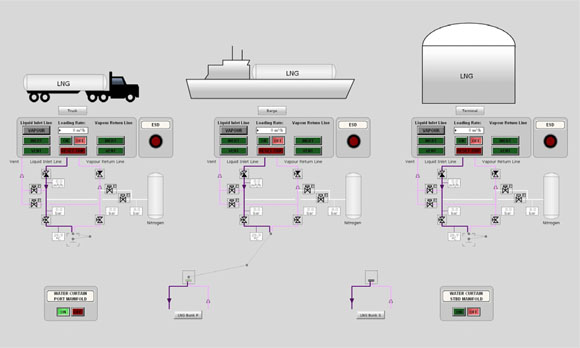

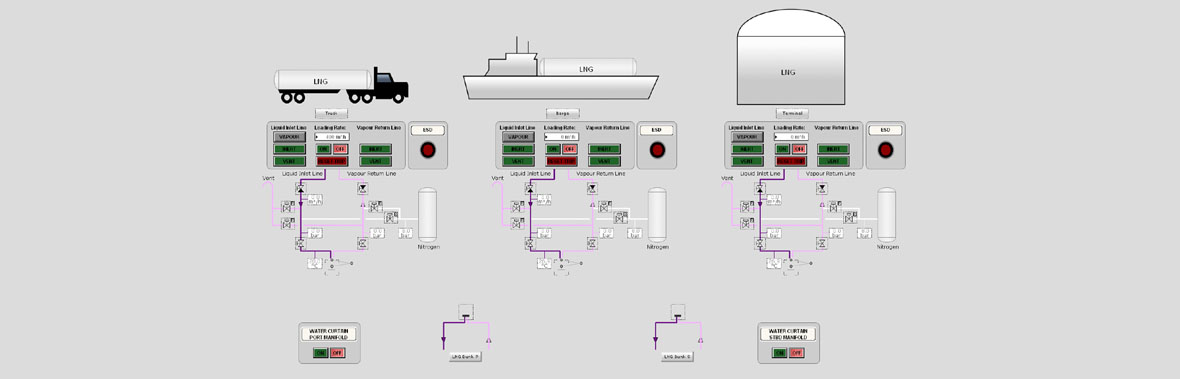

Shore side mimic: selection of barge, tank and truck, including fuel quality, methane number, Wobbe Index and density

Connection/disconnection of shore/ship/truck interface (LNG)

Flow rate control

Emergency shutdown implementation

Purging control

Capabilities to simulate effects of excess line pressures and resulting action

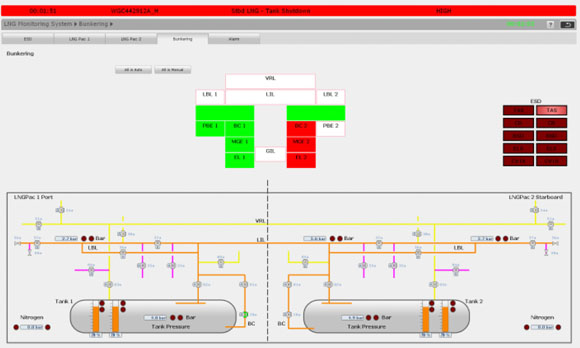

Onboard LNG storage and bunkering system

LNG monitoring system for bunker operation

LNG emergency shutdown

Gas heating

System familiarization, operations and procedures:

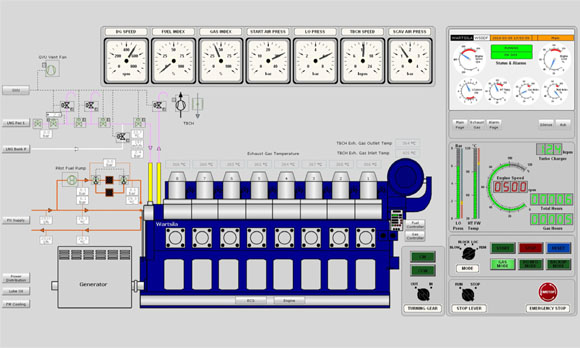

Propulsion plant Integrated Automation System (IAS)

Alarm and Safety Warning System (ASWS)

Power Management System (PMS)

Propulsion Control System (PCS)

Dual fuel diesel generator sets and support systems

Electric power supply incl. switchboards and distribution centre

Ventilation control system in machinery space

Integrated Automation System(IAS)

Fuel system is flexible architecture allows IAS(Integrated Automation System) to be used for a wide range of tasks within merchant, navy and offshore markets for highly realistic and flexible engine room and LNG bunkering simulators. The IAS is primarily an integrated system that covers the user interface for important remote control and monitoring functions in the simulator.

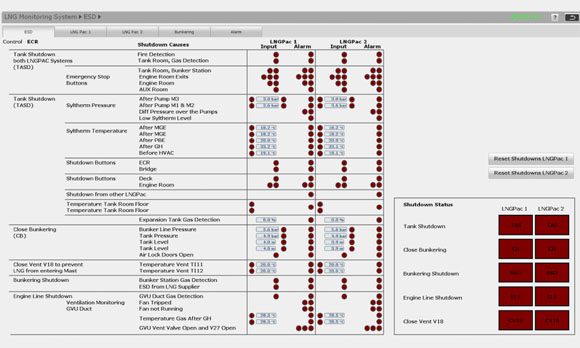

Emergency Shutdown System:

Cause& Effect Diagram with overview of all inputs and shutdowns

Inputs are both manual emergency stop buttons and process alarms

Shutdown status in all LNG Monitoring mimics

Bunkering principle STS (ship-to-ship)

Tank capacity for three days/roundtrips

Bunkering 5 -6 times every week, about 70 ton each time (SPEC 150 ton)

Separate dedicated bunker stations for LNG

Main engine running on NG when bunkering

After bunkering the bunkering line is emptied and inerted

No Methane release to air

Passengers onboard

Loading and unloading passengers and cargo while bunkering

Instructor control & Assessment

The Instructor can easily configure each Student Station to define what information shall be accessible and visible, including defining which subsystems apply to each station, and indicators that should be viewed. Instructors have access to a unique tool that allows the assessment of students on all levels, from support to management. This allows the Instructor to monitor, and use for assessment, not only alarms, but any of the available variables in the simulation model.

The assessment can be performed during simulations where the Instructor is absent. The instructor has the possibility to print out assessment reports for each individual student reflecting his performance, including pass or fail. The Instructor, Monitoring and Assessment system also has an intuitive and user-friendly feature for Recording and Replay, allowing full debrief after simulator exercises.