Technology

Design Validation and Verification Algorithm

Measurent of ice thickness

ICEFLO® that makes a remote measurement correlated to ice accumulation on a monitored surface

The objective of this test is to determine the accuracy of the ICEFLO® ice thickness measurement on its sensing surface and not to establish the accuracy of the correlation to the monitored surface. The ICEFLO® sensor and a comparison surface of the same geometry (if necessary) is subjected to the three conditions listed in SAE AS5498. The sensor and comparison surface can be subjected to the conditions at different times. The EGG can provide documentation to establish consistency of the test conditions between the ICEFLO® sensor and the comparison surface.

If utilized, the thickness of the ice accreted on the comparison surface can be used to establish the thickness measurement accuracy of the ICEFLO®.

The ICEFLO®demo nstrates compliance with the requirements of the standard (Measurement of Ice Thickness).

Measurement of Ice Thickness.

Ice Accretion Rate: If ICEFLO® has the ability to measure the ice accretion rate, then the test procedure is performed. The parameters (e.g., time) required to demonstrate compliance with the requirements of standards can be recorded.

Liquid Water Content: ICEFLO® has the ability to measure liquid water content, then the test procedure is performed. Additional test conditions are performed to demonstrate compliance with the maximum value(this value is greater than 1g/ m3). EGG can demonstrate compliance with the requirements of standards over the range specified. The test conditions listed in SAE AS5498 are performed simultaneously.

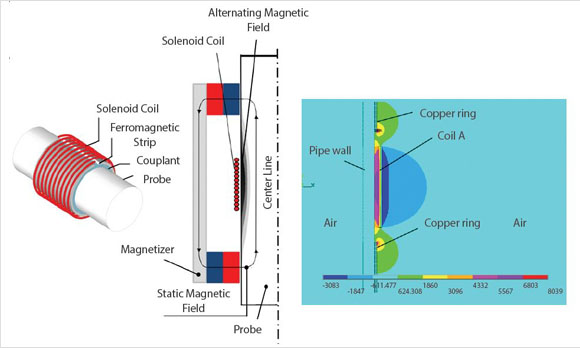

ICEFLO® Design verification

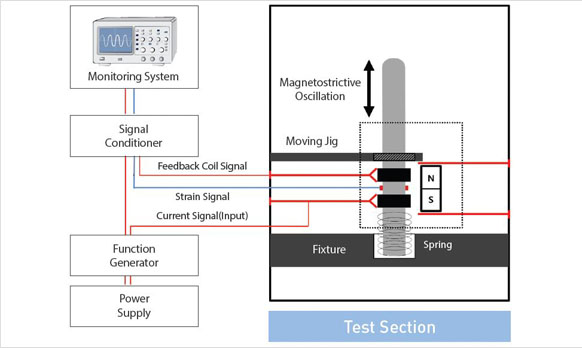

The in-flight icing detection sensor ICEFLO® is verified by the method Finite Element Method (FEM) software, COMSOL Multi-physics, to perform simulation of energy coupling behavior between electrical and magnetic energy transfer to mechanical energy of the sensing probe.

Multi-physics Simulation

Mathematical modeling for sensor structure

Electrical circuit modeling

Magnetic field analysis considering solenoids and permanent magnet

Mechanical oscillation analysis and verification of sensor characteristics

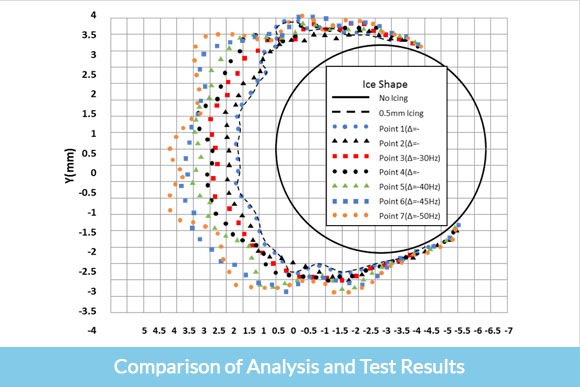

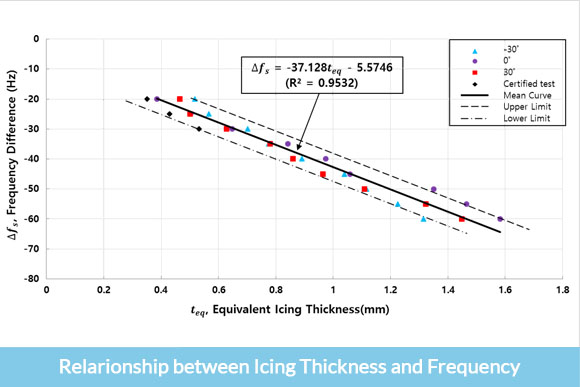

Comparison of test results and correlation

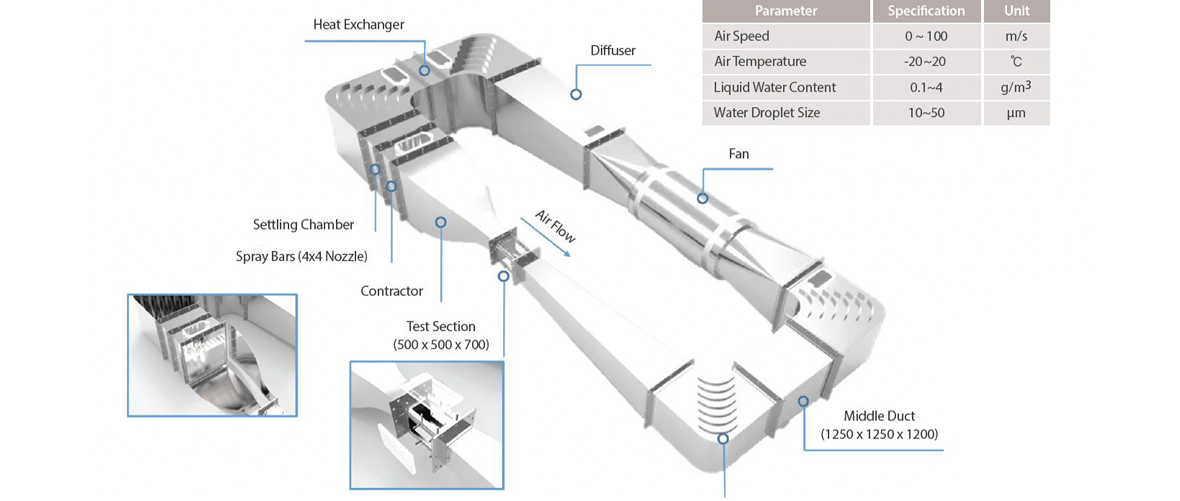

Icing chamber test in icing conditions

LWC controlled icing chamber designed by EGG

Environmental parameters as humidity, temperature, wind velocity are controlled

Icing thickness and accumulation rate measurement

Sensor function test under icing conditions

Icing parameters measured and test result from analysis

Sensor sensitivity and performance verification